One-Line Definition

IoT Automation is equal to Devices sensing, thinking, and acting on their own — making life and industries smarter.

The Internet of Things (IoT) is a network of physical devices – from sensors and machines to vehicles and appliances – embedded with connectivity that enables them to collect and share data. IoT automation refers to using these connected devices to automate tasks and processes with minimal human intervention. In essence, IoT automation transforms ordinary “things” into smart, autonomous agents that streamline workflows and drive smarter decision-making.

IoT devices are used everywhere – from factory floors to our homes – enabling real-time monitoring and control. For example, smart thermostats and lighting systems in buildings adjust environmental settings automatically for comfort and energy savings designveloper.com. By connecting physical devices to the internet, IoT automation allows “seamless data exchange and improved operational efficiency,” effectively transforming industries through real-time data processing between machines. This synergy of IoT and automation is driving the digital transformation of manufacturing, healthcare, agriculture, smart cities, and many other domains deviceauthority.com and designveloper.com.

Understanding IoT Automation

At its core, IoT automation bridges IoT and control systems. IoT provides a vast web of sensors and actuators, while automation provides the logic and control loops to use that data. Together, they enable systems that can sense, analyze, and act on the physical world autonomously. For instance, an industrial plant may deploy hundreds of IoT sensors to monitor temperature, vibration, and flow. These sensors continuously feed data to an edge or cloud platform where AI models analyze it in real time. If a machine shows anomalous vibration patterns, the system can automatically trigger a maintenance routine or adjust operating parameters.

In practice, IoT automation means embedding “smart” behavior into devices. Sensors collect environmental and operational data, the network and software analyze it (often with machine learning), and then commands are sent back to actuators or human operators. This architecture turns systems into self-regulating loops: it completes tasks without human intervention (per TechTarget)techtarget.com, optimizes resources, and adapts to changing conditions. For example, in a smart factory, conveyors and robots share data to automatically adjust speeds or routes based on current workload. In a smart home, devices like thermostats, lights, and security systems “talk” to each other via protocols (e.g. Wi-Fi, Zigbee), automatically adjusting settings for comfort and safety. Essentially, IoT automation leverages connectivity and intelligence so that systems “think and respond” on their own.

How IoT Automation Works (Sense, Analyze, Act)

IoT automation typically operates in a three-step loop:

- Sense: IoT sensors (temperature, pressure, motion, light, etc.) and connected devices continuously measure conditions. For example, a smart thermostat senses room temperature and humidity; an industrial sensor measures motor vibrations. These devices gather raw data – the “eyes and ears” of the system.

- Analyze: The collected data is transmitted (via wireless or wired networks) to processing units. Depending on latency and bandwidth requirements, data may be analyzed locally at the network edge or sent to the cloud. Edge computing allows quick, local analysis: data can be processed on-site (e.g. using an on-premises mini-server) for immediate decisions. Meanwhile, AI and ML algorithms can run either at the edge or in the cloud to detect patterns, predict failures, or optimize operations. For instance, machine-learning models may detect early signs of equipment failure by analyzing historical sensor data, enabling predictive maintenance deviceauthority.com. AI can also handle complex tasks like image or speech recognition for IoT (e.g. a camera detecting defects on an assembly line). In short, the system “thinks” by turning raw sensor inputs into actionable insights using analytics and AI.

- Act: Based on the analysis, the IoT system takes action. This may involve sending control signals to actuators (motors, pumps, valves) or triggering alerts. For example, if a sensor network detects smoke, it can automatically activate fire suppression systems; if a warehouse inventory level is low, robots can be signaled to reorder stock. These actions complete the automation loop. Importantly, some IoT systems also learn and improve over time: they adapt rules or models as they observe outcomes, creating a feedback loop for continuous improvement.

In practice, each stage (Sense → Analyze → Act) is underpinned by specific technologies (sensors/actuators, edge/cloud compute, AI models) and communication links (e.g. MQTT, CoAP, HTTP, or proprietary protocols). This structured flow – sensing real-world data, deriving insights, then executing commands – is what makes IoT automation a powerful paradigm for autonomous operations.

Key Technologies Powering IoT Automation

IoT automation relies on several core technologies working together. Key components include:

- Smart Sensors and Actuators

IoT sensors are the foundation. They can monitor nearly any physical parameter: temperature, pressure, light, motion, gas levels, pH, vibrations, and more. Modern smart sensors are often network-connected, enabling continuous data streaming. They gather real-time information about the environment or equipment performance. For example, vibration sensors on a motor can detect imbalance; camera-based vision sensors can spot manufacturing defects; wearable health sensors can track a patient’s vital signs.

Actuators are devices that execute physical actions: motors move parts, valves open/close, lights switch on/off, alarms sound, etc. An IoT controller sends commands to actuators to respond to the sensed data. For instance, a smart thermostat (sensor + actuator) will detect temperature changes and command the HVAC system to heat or cool to maintain comfort. Smart agriculture systems use soil moisture sensors to trigger irrigation pumps only when needed.

- Edge Computing

Edge computing brings data processing closer to the sensors. Instead of sending all data to a central cloud (which can introduce latency or bandwidth issues), edge devices (local gateways or micro data centers) analyze data on-site. This is crucial for real-time IoT control: immediate actions (like shutting down a machine on fault detection) cannot wait for round-trip cloud communication. By processing at the edge, IoT applications achieve faster response times, improved reliability, and reduced network load.

For example, an edge gateway in a factory might run analytics on sensor data to instantly alert supervisors about critical alarms. In smart cameras, on-device AI (edge) can identify objects or anomalies in video without streaming entire video to the cloud. Lexmark’s IoT solution exemplifies this approach by physically placing compute power at the IoT device for real-time insights. In combination with IoT, edge computing enables scalable and robust automation systems that respond in (near) real time.

- Artificial Intelligence and Machine Learning

AI/ML is increasingly integral to IoT automation. IoT systems generate vast amounts of data – big data – which is a perfect feedstock for machine learning. AI algorithms can sift through sensor streams to detect patterns, predict failures, optimize processes, and even make autonomous decisions. For instance, anomaly detection algorithms can identify irregular machine behavior before a breakdown occurs.

Advanced AI also enables “cognitive” IoT: voice assistants controlling home devices, computer vision in manufacturing quality control, or predictive analytics in supply chains. Gartner predicts that AI-native IoT applications (often called AIoT) will be among the most valuable growth drivers through 2028linkedin.com. Edge AI – running ML models on-device – allows IoT systems to make quick decisions locally (e.g. an industrial sensor notifying a machine to adjust speed). As device intelligence grows, IoT systems require less human intervention. In short, AI/ML transforms raw IoT data into actionable intelligence, making IoT automation smarter and more autonomous.

- Communication Protocols

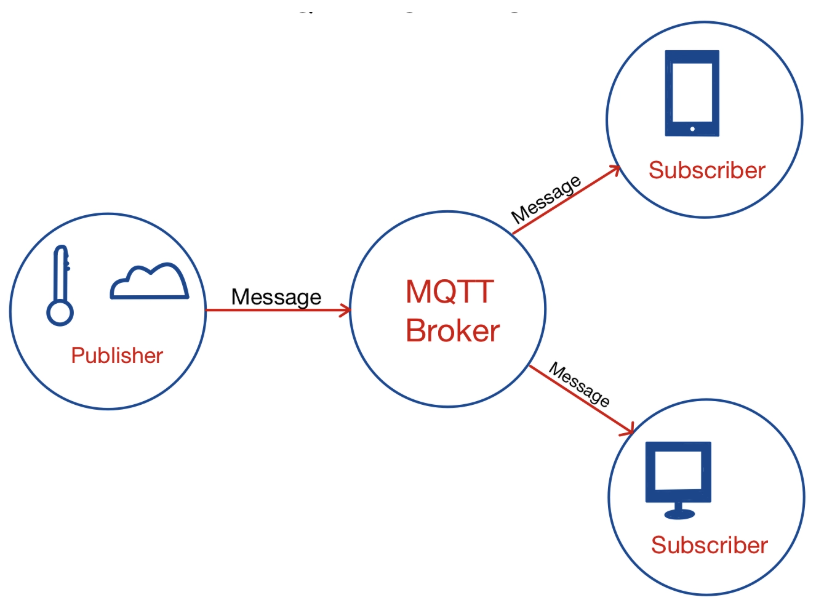

Reliable communication is the glue of IoT automation. IoT devices use a variety of protocols to exchange data. Common ones include MQTT (a lightweight publish/subscribe protocol), CoAP (optimized for constrained devices over UDP), HTTP/HTTPS (standard web protocols), and message brokers like AMQP. Wireless protocols such as Wi-Fi, Bluetooth, Zigbee, Thread, LoRaWAN(read more), and 5G provide the network layer that connects devices.

Benefits of IoT Automation

Implementing IoT automation yields many advantages across industries:

- Increased Efficiency and Productivity – Automated IoT systems can run 24/7 and handle high workloads. Real-time analytics and machine autonomy reduce downtime and speed up processes.

- Cost Savings – By automating routine tasks, companies save on labor and operational costs. Energy costs drop when IoT regulates heating, lighting, or industrial motors only when needed.

- Scalability and Flexibility – IoT solutions are inherently scalable. New devices and sensors can be added incrementally, and cloud-based platforms can grow to accommodate more data.

- Enhanced Safety and Security – IoT automation significantly improves safety by replacing or assisting humans in hazardous tasks. Sensors can continuously monitor dangerous zones and trigger alarms or shutdowns if thresholds are crossed.

Foundation of IoT click